Variance Calculation determines differences between the actual costs incurred on a production order and the standard costs of the material produced. Variances are calculated not at once, but for different variance categories. The variances computed are then transferred to CO-PA.

- Define Variance Keys

The Variance Key is part of the order header and controls variance calculation. The system selects the value set by this step as default value when a material master is created. From the material master, the variance key is then transferred to the order when an order for the material is created.

In Product Cost by Order you usually calculate the variances cumulatively.

In cumulative variance calculation, the target costs are calculated on the basis of the quantity you have transferred to stock for the order. The actual costs are for the entire life of the order. Variance calculation requires that the order have the status DLV (delivered) or TECO (technically completed).

In Product Cost by Period, you always calculate the variances periodically.

In variance calculation by period, the target costs are calculated on the basis of the quantity that you delivered to stock in the period. The actual costs are only for the period in which you calculate variances. Variance calculation requires that a goods receipt was posted for the order in the period. If that is not the case, the system only calculates remaining variances.

- Check Variance Variants

In this step you define the variance variants. Variance variants determine what variance categories are calculated.

- Define Target Cost Versions

The target cost version controls various parameters related to calculation of target costs in variance calculation. In variance calculation, target costs are needed as a comparison to the actual costs incurred.

Target cost versions are used in the variance calculation in the following ways:

- To control which variance (total variance, production variances or planning variance) is calculated

- To valuate unplanned scrap (scrap variance) Unplanned scrap is valuated in the period-end closing activities when the variances are calculated. You can specify in a valuation variant for WIP and scrap which cost estimate you want to use to calculate the target costs for the valuation of unplanned scrap. You assign the valuation variant to target cost version 0 if you want to include it in the valuation of scrap

- Define PA Transfer Structure for Settlement Procedure

When variances are calculated in Cost Object Controlling (CO-PC), production variances are determined and stored. When you settle production orders, you can transfer these variances – differentiated by cost element and variance category – to value fields in CO-PA.

Although it is technically possible, via a joint maintenance dialog, to use the same PA transfer structures from different allocation types to settle production variances, you should instead define separate PA transfer structures.

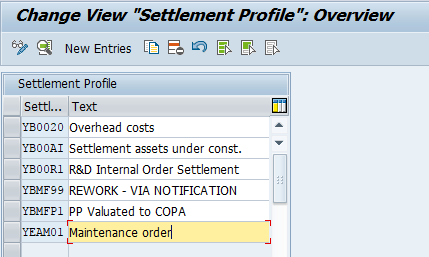

- Create Settlement Profile

The settlement profile controls various parameters related to settlement.

| Profile | Text |

| YBMFP1 | PP Valuated to COPA |

| YBMF99 | Rework – Via Notification |

Thank You

Jayanth